A Comprehensive Guide

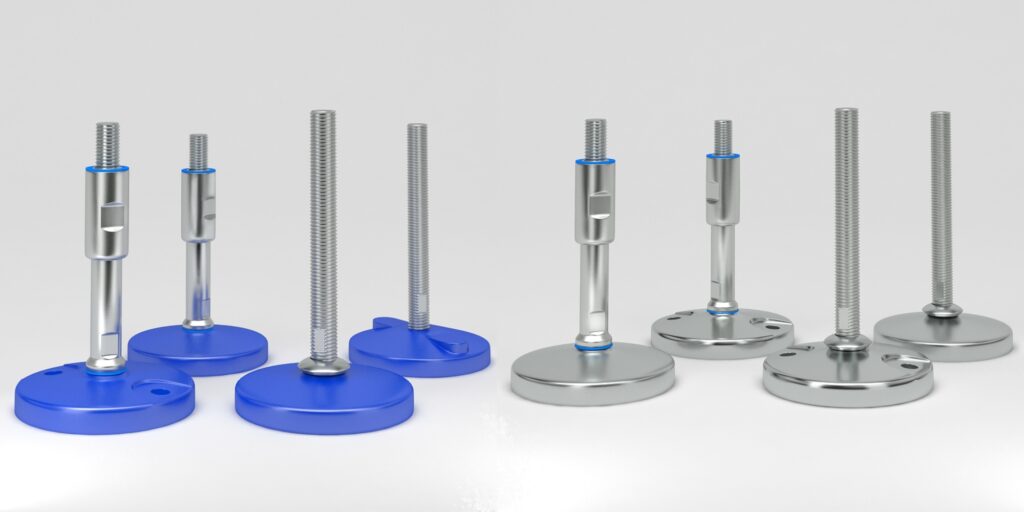

In the world of industrial equipment and machinery, the importance of robust support systems cannot be overstated. Among these support systems, stainless steel and composite solid base feet play a crucial role in ensuring stability, safety, and durability. These components are essential for various applications, ranging from manufacturing and food processing to pharmaceuticals and beyond. This article explores the benefits, applications, and key considerations of stainless steel and composite solid base feet, highlighting why they are integral to modern industry.

The Importance of Base Feet in Industrial Applications

Base feet, often referred to as machine feet or leveling feet, are critical components that provide stability and support to machinery and equipment. They help in leveling equipment on uneven surfaces, reducing vibrations, and preventing damage to floors. Properly designed and installed base feet contribute to the efficiency and longevity of machinery, ensuring optimal performance and safety.

Stainless Steel Base Feet

Advantages of Stainless Steel

- Corrosion Resistance: Stainless steel is renowned for its exceptional resistance to corrosion and rust, making it ideal for environments exposed to moisture, chemicals, and other corrosive elements. This makes stainless steel base feet a preferred choice in industries such as food processing, pharmaceuticals, and marine applications.

- Strength and Durability: Stainless steel offers high tensile strength, which translates into enhanced durability and load-bearing capacity. This makes it suitable for supporting heavy machinery and equipment.

- Hygienic Properties: The smooth surface of stainless steel is easy to clean and sanitize, making it an excellent choice for applications requiring stringent hygiene standards, such as food and beverage processing and healthcare facilities.

- Aesthetic Appeal: Stainless steel base feet provide a sleek and professional appearance, which can enhance the overall look of machinery and equipment in commercial settings.

Applications of Stainless Steel Base Feet

- Food and Beverage Industry: Used in processing equipment, conveyor systems, and storage units where hygiene and corrosion resistance are paramount.

- Pharmaceutical Industry: Utilized in laboratory equipment, production lines, and storage systems.

- Marine Industry: Ideal for supporting equipment exposed to saltwater and harsh marine environments.

Composite Solid Base Feet

Advantages of Composite Materials

- Lightweight: Composite materials are significantly lighter than metals, making them easier to handle and install without compromising strength.

- Corrosion Resistance: Similar to stainless steel, composites are resistant to corrosion, making them suitable for various environments.

- Electrical Insulation: Composites offer excellent electrical insulating properties, making them suitable for applications where electrical conductivity is a concern.

- Cost-Effective: Composite base feet can be more cost-effective than metal alternatives, offering a balance between performance and affordability.

Applications of Composite Solid Base Feet

- Electronics and Telecommunications: Used in equipment racks and cabinets where electrical insulation is crucial.

- Manufacturing Industry: Suitable for supporting lightweight machinery and assembly lines.

- Chemical Processing: Ideal for environments where exposure to corrosive substances is common.

Key Considerations When Choosing Base Feet

Load Capacity

One of the most critical factors to consider is the load capacity of the base feet. It is essential to select base feet that can support the weight of the equipment and any additional loads without compromising stability.

Environmental Conditions

The operating environment plays a significant role in determining the appropriate material for base feet. For corrosive environments, stainless steel or composite materials with high corrosion resistance are recommended.

Hygiene Requirements

In industries such as food processing and pharmaceuticals, where hygiene is a top priority, stainless steel base feet are preferred due to their ease of cleaning and resistance to contamination.

Vibration Damping

For equipment that generates significant vibrations, selecting base feet with vibration damping capabilities is crucial to prevent equipment damage and ensure smooth operation.

Installation and Adjustability

Ease of installation and adjustability is important for ensuring that equipment is level and stable. Base feet with adjustable heights and easy installation features can save time and effort during setup.

Stainless steel and composite solid base feet

Stainless steel and composite solid base feet are indispensable components in modern industrial settings. Their ability to provide stability, support, and durability makes them essential for various applications across multiple industries. Stainless steel offers unmatched corrosion resistance and strength, making it ideal for demanding environments, while composite materials provide a lightweight, cost-effective solution with excellent insulating properties. By carefully considering factors such as load capacity, environmental conditions, and hygiene requirements, businesses can select the appropriate base feet to enhance the performance and longevity of their equipment.

Final Thoughts

Investing in high-quality base feet is a proactive step toward ensuring the efficiency and safety of industrial operations. Whether opting for the robustness of stainless steel or the versatility of composite materials, selecting the right base feet can significantly impact productivity and operational success. As industries continue to evolve and demand more advanced solutions, the role of base feet in supporting innovation and excellence remains ever crucial.