The Essential Guide

In various industrial and commercial applications, ensuring stability and balance is crucial for the optimal performance of machinery and equipment. The right type of feet and leveling solutions can make all the difference in maintaining equipment efficiency, safety, and hygiene standards. This article delves into the world of stainless steel solid base feet, machine feet, hygienic leveling feet, industrial leveling feet, and sanitary adjustable feet. We’ll explore their applications, benefits, and the factors to consider when choosing the right solution for your needs.

Understanding Stainless Steel Solid Base Feet

Stainless steel solid base feet are an integral component in many industrial settings. These feet are designed to provide a sturdy and stable base for machines and equipment, preventing movement and vibration that can lead to operational inefficiencies and safety hazards. Made from high-quality stainless steel, these solid base feet offer superior durability and resistance to corrosion, making them ideal for harsh environments.

Benefits of Stainless Steel Solid Base Feet

- Durability: Stainless steel is renowned for its strength and long-lasting properties, ensuring that solid base feet can withstand heavy loads and challenging conditions.

- Corrosion Resistance: The material’s inherent resistance to rust and corrosion makes these feet suitable for use in environments exposed to moisture and chemicals.

- Easy Maintenance: Stainless steel feet are easy to clean and maintain, which is particularly beneficial in industries with strict hygiene requirements.

- Versatility: These feet are suitable for a wide range of applications, from manufacturing plants to food processing facilities.

Machine Feet: Ensuring Stability and Efficiency

Machine feet are adjustable components used to level and stabilize machinery and equipment. These feet play a critical role in reducing vibrations, enhancing performance, and preventing damage to equipment and surfaces.

Types of Machine Feet

- Fixed Machine Feet: Designed for applications where movement is minimal, providing a robust and stable base.

- Adjustable Machine Feet: Allow for height adjustments to ensure precise leveling on uneven surfaces.

Advantages of Machine Feet

- Improved Stability: By leveling machinery, machine feet help prevent unwanted movement and vibrations that can affect performance and lead to mechanical failures.

- Enhanced Safety: Properly leveled equipment reduces the risk of accidents and injuries in the workplace.

- Prolonged Equipment Life: Minimizing vibrations and movement helps extend the lifespan of machinery by reducing wear and tear.

Hygienic Leveling Feet: Meeting Sanitary Standards

In industries where hygiene is paramount, such as food processing and pharmaceuticals, hygienic leveling feet are essential. These feet are designed to meet strict sanitary standards, ensuring that equipment remains clean and safe for use.

Features of Hygienic Leveling Feet

- Smooth Surfaces: Hygienic feet often feature smooth, polished surfaces that are easy to clean and disinfect.

- Corrosion-Resistant Materials: Made from stainless steel or other non-corrosive materials to prevent contamination.

- Sealed Design: Often designed with seals or covers to prevent the accumulation of dirt and bacteria.

Benefits of Hygienic Leveling Feet

- Compliance with Regulations: Helps businesses comply with health and safety regulations by maintaining high hygiene standards.

- Easy Cleaning: Simplifies the cleaning process, reducing downtime and maintenance costs.

- Prevention of Contamination: Minimizes the risk of contamination, ensuring product safety and quality.

Industrial Leveling Feet: Versatile and Reliable Solutions

Industrial leveling feet are versatile components used across various sectors, including manufacturing, healthcare, and hospitality. These feet are designed to provide stability and support to equipment, ensuring optimal performance and safety.

Applications of Industrial Leveling Feet

- Manufacturing: Used in assembly lines, conveyor systems, and heavy machinery to maintain stability and efficiency.

- Healthcare: Employed in medical equipment and laboratory setups to ensure precise and accurate operations.

- Hospitality: Utilized in commercial kitchens and dining facilities to keep appliances and furniture level and secure.

Choosing the Right Industrial Leveling Feet

When selecting industrial leveling feet, consider factors such as load capacity, adjustability, material, and environmental conditions. Stainless steel options are often preferred for their durability and resistance to corrosion.

Sanitary Adjustable Feet: Combining Hygiene and Flexibility

Sanitary adjustable feet are specifically designed to offer both hygiene and flexibility in applications that demand cleanliness and adaptability. These feet are essential in environments where frequent cleaning and equipment adjustments are required.

Key Features of Sanitary Adjustable Feet

- Adjustability: Allows for easy height adjustments to accommodate different equipment and surfaces.

- Hygienic Design: Features smooth, crevice-free surfaces that prevent the buildup of bacteria and contaminants.

- Durability: Made from high-quality materials that withstand rigorous cleaning and sanitizing processes.

Advantages of Sanitary Adjustable Feet

- Adaptability: Easily adjustable to fit various applications, providing versatility and convenience.

- Hygiene Assurance: Meets strict hygiene standards, making them ideal for food processing, pharmaceuticals, and healthcare settings.

- Long-lasting Performance: Offers reliable performance and longevity, even in challenging environments.

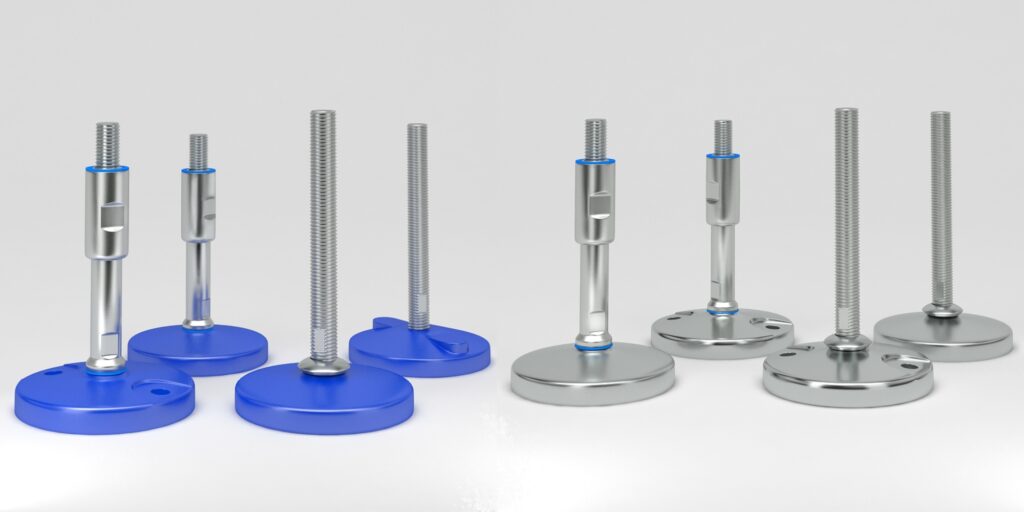

Stainless steel and composite solid base feet

Stainless steel solid base feet, machine feet, hygienic leveling feet, industrial leveling feet, and sanitary adjustable feet are essential components in numerous industries. They provide stability, safety, and hygiene, ensuring optimal performance and compliance with regulations. When selecting the right feet for your application, consider factors such as material, load capacity, adjustability, and environmental conditions. By choosing the appropriate leveling solution, you can enhance the efficiency and safety of your equipment, ultimately contributing to the success of your operations.